How Our Metal Frames Are Made – Quality from the Ground Up

At the heart of exceptional furniture lies the foundation that supports it – precision-engineered metal frames crafted with unwavering attention to detail . As a Polish company proudly operating in Ireland, we represent the perfect fusion of European craftsmanship heritage and modern manufacturing innovation . Our metal frames are not merely structural components; they are the result of combining traditional metalworking skills, cutting-edge technology, and an uncompromising passion for quality that defines every piece we create .

What sets us apart in the competitive furniture manufacturing landscape is our commitment to complete in-house production control . Every stage of our manufacturing process – from the initial conceptual design through precision welding to the final powder coating finish – takes place within our dedicated workshop facilities . This vertical integration approach ensures that we maintain the highest quality standards while guaranteeing consistency across our entire product range .

Professional metalworking workshop showcasing metal frame production process

The Polish Furniture Manufacturing Excellence

Poland’s position as a global furniture manufacturing leader provides our company with significant advantages in terms of material access, skilled labor, and industry expertise . As the world’s second-largest furniture exporter and first in Europe, Poland combines competitive production costs with exceptional quality standards, creating optimal conditions for premium furniture manufacturing 34. The country’s furniture industry employs approximately 200,000 people across more than 32,000 companies, generating record sales of over PLN 68 billion in 2022 .

The Polish furniture industry’s success stems from combining traditional craftsmanship heritage with modern manufacturing technology . This synthesis enables producers to create furniture that satisfies contemporary design requirements while maintaining the quality standards associated with European manufacturing . Our company leverages this broader industry strength while focusing specifically on metal frame applications and precision manufacturing .

Polish manufacturers maintain competitive advantages through access to high-quality materials and advanced manufacturing capabilities . The furniture market in Poland contributes 2.3% of Polish GDP, the highest share compared to other EU countries producing furniture . This strong foundation supports our commitment to delivering exceptional metal frames that meet the demanding requirements of modern furniture applications .

Specializing in Metal Frame Excellence

Our expertise lies in creating metal frames for three core product categories: sophisticated loft furniture, precision-engineered table legs, and distinctive industrial shelving systems . Each piece combines the raw authenticity of industrial materials with the refined functionality demanded by modern lifestyles . The characteristic elements of loft design – concrete aesthetics, metal accents, open spatial concepts, and minimalist approaches – require furniture that complements these architectural features while providing practical functionality .

Modern loft-style dining table with precision metal X-frame legs

The enduring popularity of loft style reflects its unique ability to create atmospheres that feel both modern and timeless. This aesthetic approach emphasizes honest material expression, where steel, wood, and other components display their inherent characteristics rather than concealing them beneath superficial treatments . Our manufacturing philosophy aligns perfectly with these principles, producing furniture frames that celebrate the beauty of well-crafted metalwork .

Industrial furniture offers exceptional advantages including durability, strength, and design flexibility . These pieces are typically composed of high-grade materials including stainless steel and seasoned components, designed to bring longevity and durability to any application . Due to their strength and durability, industrial-style furniture can be quite useful for those who are constantly engaged in heavy-duty activities or want assurance that their furniture will last for extended periods

Contemporary metal frame bench featuring premium upholstery and sleek design

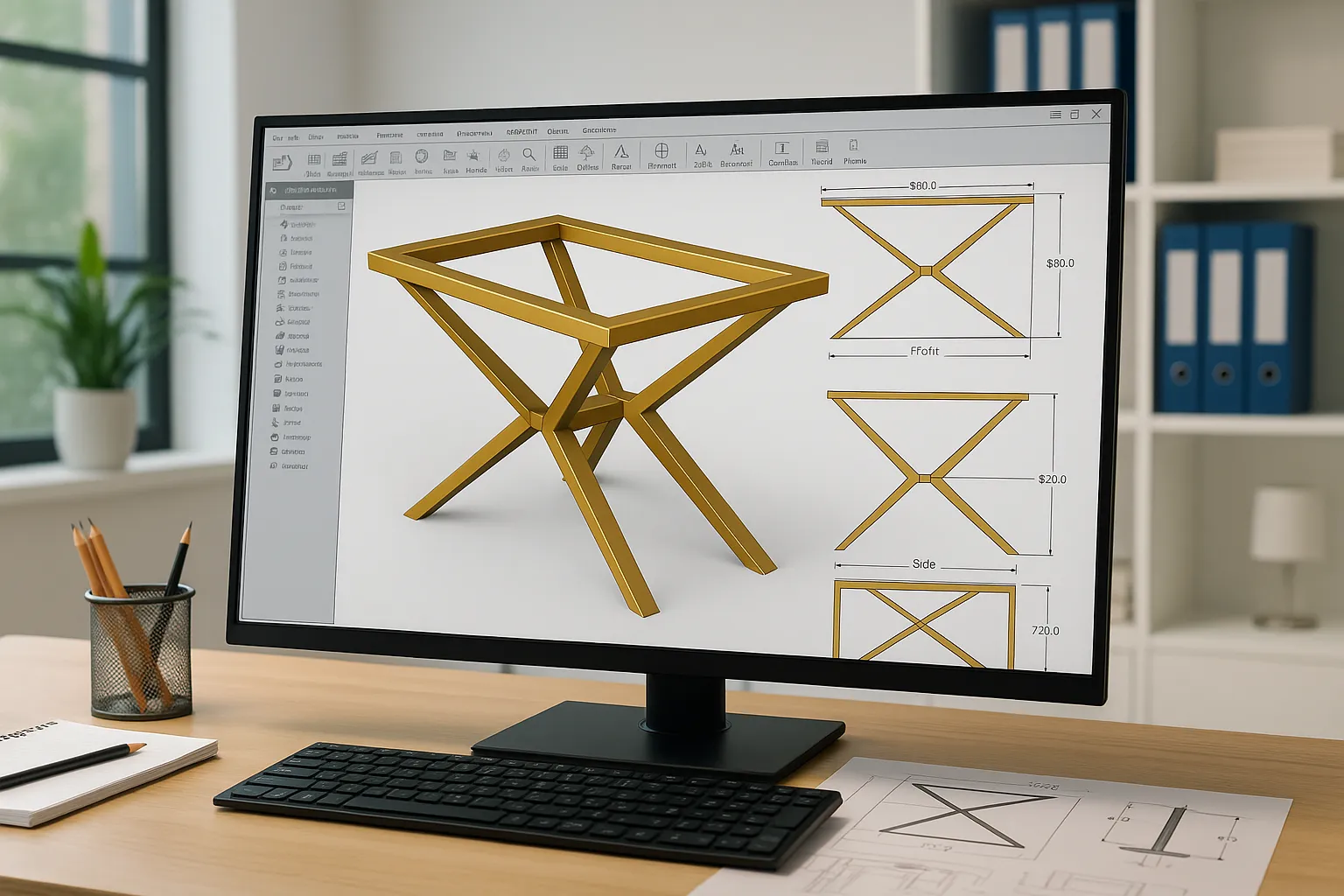

Advanced 3D Modeling and Design Integration

Our manufacturing process begins with sophisticated 3D modeling capabilities that enable precise visualization and planning before physical production commences . Advanced computer-aided design (CAD) software allows us to create photorealistic representations of furniture designs, enabling real-time adjustments and comprehensive exploration of design variations . This digital-first approach eliminates costly errors while facilitating collaborative design processes with clients and stakeholders .

3D furniture visualization provides significant advantages over traditional prototyping methods, which can be expensive, time-intensive, and material-wasteful . Digital modeling enables rapid iteration, allowing designers to explore multiple design options without committing resources to physical prototypes . This approach enhances decision-making capabilities while reducing development timelines and costs associated with new product introduction .

The precision and accuracy provided by 3D CAD modeling services create detailed models that account for every dimension and feature of furniture . This level of precision helps reduce errors during production while enabling faster prototyping and fewer revisions .The integration of 3D modeling with manufacturing processes ensures seamless transition from design concept to physical production .

Comprehensive Six-Stage Manufacturing Excellence

Stage 1: Design and Planning – Precision from the First Millimeter

Every manufacturing project begins with detailed digital planning that establishes exact specifications for all components and processes .Our 3D modeling capabilities enable comprehensive visualization of finished products, allowing for optimization of both aesthetic and functional characteristics before production begins .This planning phase includes material calculations, load analysis, and finish specifications that guide subsequent manufacturing operations .

Digital planning eliminates the possibility of errors that could compromise quality or require costly corrections during production .By establishing precise specifications at the design stage, we ensure that all subsequent operations proceed according to predetermined parameters. This systematic approach contributes to the consistency and reliability that characterizes professional furniture manufacturing .

Stage 2: Premium Materials – Certified Steel from Trusted Sources

Our commitment to excellence begins with careful selection of certified steel materials from verified suppliers who meet stringent quality standards . Each steel profile undergoes comprehensive inspection before entering our processing workflow, ensuring elimination of defects or imperfections that could compromise final product quality . This material selection process reflects industry best practices, where raw material quality directly influences structural integrity, durability, and overall product performance .

Steel’s exceptional strength-to-weight ratio makes it ideal for furniture applications requiring both structural integrity and design flexibility . The material’s resistance to deformation under load ensures long-term dimensional stability, while its adaptability to various finishing processes enables diverse aesthetic treatments .Our material selection process prioritizes steel grades that provide optimal performance characteristics for furniture applications .

Quality control protocols implemented at the material reception stage include dimensional verification, surface inspection, and certification documentation review .These procedures ensure that only materials meeting our specifications enter the production process, maintaining consistency across all manufactured products . Investment in premium materials reflects our commitment to producing furniture that meets the highest standards for durability and performance .

Stage 3: Cutting and Preparation – Japanese Precision

Material cutting operations utilize Japanese Makita rotary saws renowned for their exceptional accuracy and consistent performance characteristics . These professional-grade tools feature precision-engineered components that provide enhanced cutting accuracy while reducing vibration and improving operator control The cutting depth capabilities of these saws accommodate various steel profile dimensions efficiently, while integrated features improve cut-line visibility for enhanced accuracy

Makita circular saws are designed to provide precision cutting, allowing achievement of clean, straight cuts with ease . The tool’s blade is engineered to maintain consistent speed and stay on track, ensuring smooth, accurate cuts every time . These saws deliver high performance and durability with powerful motors and strong blades that can handle tough cutting jobs with ease.

Precision cutting directly impacts subsequent assembly operations, as properly sized components ensure optimal fit during welding and assembly processes .. The consistency achieved through high-quality cutting equipment reduces waste, minimizes rework requirements, and contributes to overall manufacturing efficiency . Investment in premium cutting technology reflects our commitment to achieving the highest possible standards throughout the manufacturing process .

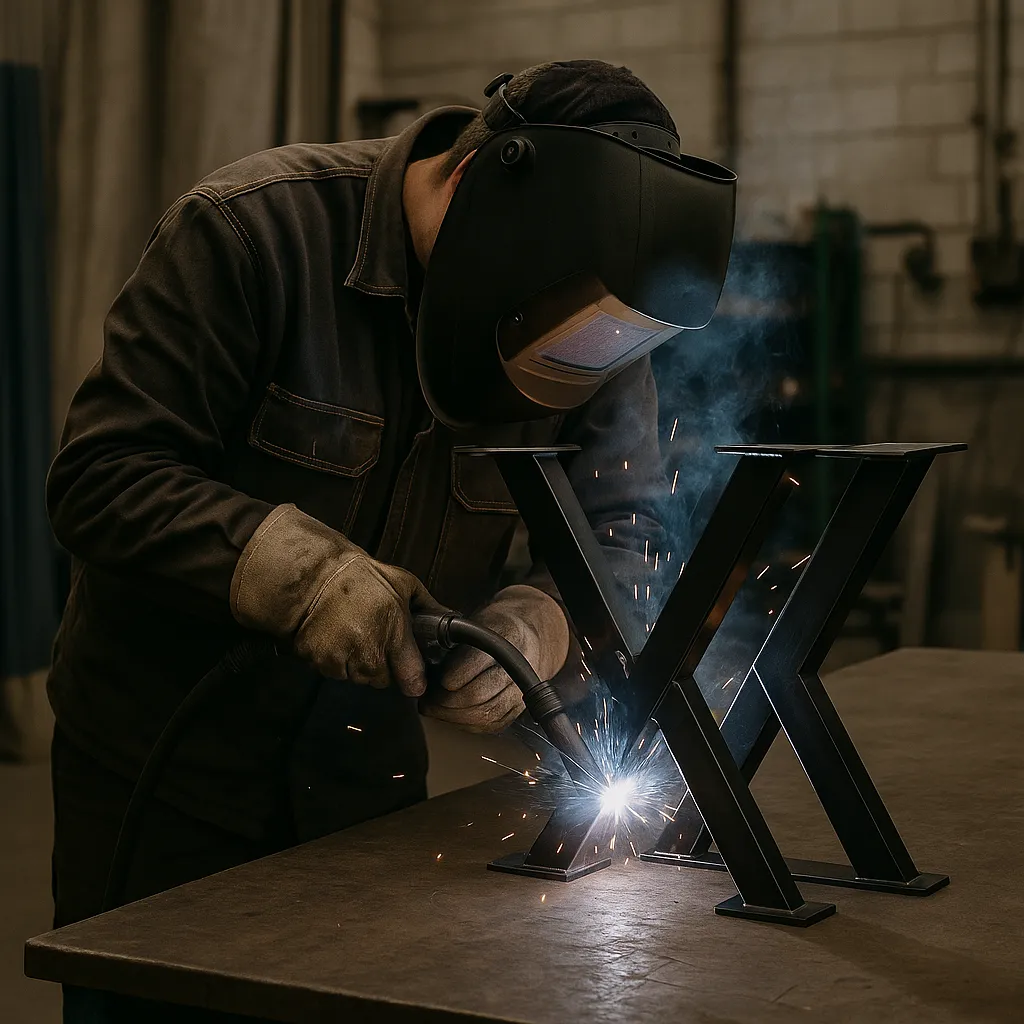

Stage 4: Welding – Strength and Stability

Our welding operations employ Metal Inert Gas (MIG) welding techniques within carefully controlled protective atmospheres composed of noble gases and carbon dioxide .. This welding method ensures formation of strong, durable joints capable of withstanding demanding use conditions while maintaining structural integrity over extended periods .MIG welding offers significant advantages including faster operation speeds, deeper penetration capabilities, and superior process control compared to alternative welding methods.

MIG welding uses an electric arc between the workpiece and a continuously fed wire electrode . When the wire contacts the base metal, electrical current creates an arc that melts both the wire and the material’s surface .The molten metal from the wire combines with the melted base metal, forming a strong bond as it cools and solidifies .

Strategic profile positioning during welding operations minimizes visible weld seams while maximizing structural strength and aesthetic appeal . All welding operations occur on professional welding tables that prevent distortion while maintaining repeatable quality standards across multiple production runs. Professional welding table utilization provides stable, flat reference surfaces essential for maintaining dimensional accuracy while supporting heavy workpieces during welding operations.

Stage 5: Four-Stage Grinding and Finishing Excellence

Post-welding finishing involves systematic four-stage grinding processes that transform welded structures into refined, aesthetically pleasing components ready for final coating . This comprehensive approach begins with coarse grinding operations that remove excess weld material and surface irregularities, followed by progressively finer grinding stages that achieve increasingly smooth surface finishes . Edge polishing and smoothing operations create clean transitions between surfaces, while manual finishing ensures every detail meets our quality standards .

Our grinding operations exclusively utilize premium 3M Cubitron abrasive products incorporating advanced ceramic grain technology for superior performance characteristics . These precision-shaped ceramic grains cut faster than conventional abrasives while providing extended service life and consistent results across varying grinding pressures . The triangular grain structure continuously fractures during use to maintain sharp cutting edges, resulting in cooler cutting action and reduced operator fatigue .

3M Cubitron II Abrasive technology uses triangular-shaped finishing grain to deliver unparalleled cutting and grinding results . Each grain is electrostatically oriented to form razor-sharp peaks that all slice in concert together, producing remarkably even and precise results . The precision-shaped ceramic grains also sharpen themselves as they fracture as part of the natural wear process, ensuring consistent performance throughout their service life .

Stage 6: Advanced Powder Coating Application

The final manufacturing stage involves comprehensive surface preparation followed by electrostatic powder coating application and thermal curing processes . Surface preparation includes both manual cleaning and chemical treatment designed to remove all traces of contaminants that could compromise coating adhesion . This meticulous preparation ensures optimal powder coating performance and longevity under various environmental conditions .

Powder coating application occurs within controlled spray booth environments where electrostatically charged resin particles adhere to positively charged frame surfaces .This electrostatic attraction ensures uniform coating distribution across complex geometries while minimizing material waste .

The dry powder coating process offers significant environmental advantages over traditional liquid painting methods, producing virtually no organic waste while eliminating harmful solvents .

Thermal curing at approximately 180°C initiates polymerization processes that transform applied powder into hard, durable finishes. This curing process creates protective coatings offering superior resistance to scratching, chipping, fading, and discoloration compared to conventional paint finishes .Powder coating finishes can last for up to 20 years before requiring reapplication, providing exceptional rust resistance and chip resistance.

Industrial loft-style shelving system with precision-welded metal frame

Quality Standards and European Compliance

Our manufacturing processes adhere to comprehensive European furniture standards including EN for domestic seating, which specifies minimum requirements for safety, strength, and durability of all types of domestic seating for adults . These standards address critical aspects including load-bearing requirements, material safety specifications, and durability characteristics that ensure consumer safety and product reliability . The tests are based on use by persons weighing up to 110 kg, ensuring robust performance under normal usage conditions .

Quality control implementation involves systematic inspection procedures at each manufacturing stage, from initial material reception through final product completion . This approach enables early detection and correction of potential issues before they impact final product quality . Documentation of quality control procedures and results provides complete traceability throughout the manufacturing process while supporting continuous improvement initiatives .

European standards ensure that furniture products meet stringent requirements for structural integrity and user safety . All kinds of domestic seating including chairs, upholstered chairs, and sofas can be assessed according to these standards . Compliance with established European standards demonstrates our commitment to producing furniture that meets or exceeds customer expectations .

Market Leadership and Design Excellence

The growing presence of Polish manufacturing companies in Ireland reflects broader trends in European industrial development, where companies leverage complementary strengths of different national markets . Polish-Irish business relationships have experienced significant growth, with continued expansion expected as companies recognize mutual benefits of this collaboration . Our cross-cultural manufacturing approach combines Polish craftsmanship traditions with Irish business practices to deliver exceptional value .

Design excellence represents a critical factor in international market success, with Polish furniture manufacturers demonstrating remarkable flexibility and innovation in design, sourcing, and production areas . This design capability, combined with competitive manufacturing costs and high-quality materials, positions Polish companies favorably in global markets . Polish furniture is often found in international homes, appreciated for its quality, fashionable design, functionality, and adaptability to different unit sizes .

The Irish furniture market provides excellent opportunities for specialized manufacturers focusing on high-quality furniture applications . Despite challenges in 2024, which saw a 5% decrease in Polish furniture production, some segments including kitchen and bedroom furniture recorded increases . This market environment supports companies that maintain focus on quality and specialized applications .

Sustainability and Environmental Responsibility

Modern furniture manufacturing must address environmental concerns while maintaining quality and performance standards . Our powder coating processes eliminate harmful solvents and reduce organic waste compared to traditional painting methods . This environmentally responsible approach aligns with broader sustainability goals while providing superior product performance and durability .

Material selection emphasizes certified steel from suppliers meeting environmental and quality standards . Responsible sourcing practices ensure that our raw materials support sustainable manufacturing while maintaining the quality characteristics essential for premium furniture production. These practices reflect our commitment to environmental stewardship throughout the supply chain .

Manufacturing efficiency improvements reduce material waste while optimizing energy consumption across production processes . Systematic approaches to quality control minimize rework requirements, reducing both material consumption and energy usage . These efficiency gains contribute to environmental sustainability while supporting cost-effective manufacturing operations .

Innovation and Future Development

Continuous improvement initiatives focus on enhancing manufacturing processes, expanding design capabilities, and developing new product applications . Modular design principles enable furniture systems that adapt to changing user requirements while maintaining aesthetic integrity . This adaptability reflects broader trends toward flexible living and working environments where furniture must accommodate evolving needs .

Technology integration continues to enhance manufacturing capabilities through improved design software, advanced manufacturing equipment, and enhanced quality control systems. These technological advances enable more precise manufacturing while reducing production time and costs . Investment in advanced technology supports our commitment to maintaining leadership in metal frame manufacturing .

Research and development efforts explore new applications for industrial design principles across various furniture categories . This exploration includes investigating new materials, manufacturing techniques, and design approaches that could enhance product performance while expanding market opportunities . Innovation initiatives ensure our continued leadership in the evolving furniture market .

Conclusion: Excellence Through Specialization

Our specialized focus on metal frame manufacturing enables us to deliver unmatched expertise in industrial design applications . This concentration allows us to understand market requirements deeply while developing manufacturing capabilities specifically optimized for furniture applications . The result is furniture frames that satisfy both functional requirements and aesthetic aspirations of customers seeking authentic craftsmanship .

The combination of Polish manufacturing heritage, Irish business acumen, and specialized market focus creates a unique value proposition in the competitive furniture market . Our commitment to quality at every stage – from material selection through final inspection – ensures that every product bearing our name meets the exacting standards that define our brand .Through this dedication to excellence, we continue building the foundation of quality that characterizes premium furniture manufacturing .

Every metal frame that emerges from our workshop represents the culmination of careful planning, premium materials, precision manufacturing, and rigorous quality control . Our six-stage production process ensures that each component meets the highest standards for structural integrity, aesthetic appeal, and long-term durability . The integration of advanced manufacturing technologies with traditional craftsmanship skills creates products that satisfy both functional requirements and design aspirations .

We build frames that are the foundation of the quality behind our furniture .

See more at www.pouffelove.ie

Or explore our metal bench collection: pouffelove.ie/furniture/metal-frame-benches